Wolf understands the difficulty of controlling costs during the prototype phase of development. Through the use of 3D modeling, systems analysis and design for manufacturing, we maximize the design's form, fit and function before going through the expense of having parts made. We can easily test proof of concept with our in-house 3D printing and milling capabilities.

Our ongoing relationships with suppliers can move our customer from concept to finished parts in a matter of days or weeks instead of months or years.

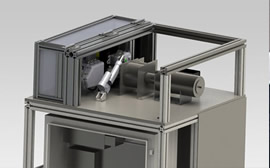

3D printer

Lathe

Modeling and Simulations

Wolf uses 3D modeling and simulation as an analysis, design and validation tool on most projects. Using 3D models and physics-based simulation, we quickly and thoroughly investigate numerous design parameters, thereby minimizing overall design cost by decreasing expensive testing and redesign. We can model your product or process during the pre-design stage to demonstrate feasibility and to aid in visualization.

We can also use modeling and simulation to analyze product performance in use scenarios that are not testable in the laboratory. We develop many of our own computer models and simulations in several host environments, and we possess numerous off-the-shelf simulation tools used across various industries. Our modeling and simulation capabilities encompass mechanical, electrical, signal processing, magnetic, optical and biomechanical processes.