CNC mill

We provide a range of engineering services to support and leverage the creativity of your staff, while reducing your costs and lowering your overhead. We will use our skills to meet your needs, either by performing a comprehensive design service to take your ideas from concept to manufacturing, or by providing a design, analysis, or optimization service to supplement your in-house engineering skills.

Manufacturing Engineering

Wolf uses design-for-manufacturing principles in all our design engineering projects. Throughout the design process, Wolf designs with manufacturability, assembly, maintenance, environmental compliance and the end user in mind. We successfully manage project costs for our customers by reducing parts count and complexity. Wolf designs exploit the use off the shelf components in place of expensive machined components where possible.

Wolf uses design-for-manufacturing principles in all our design engineering projects. Throughout the design process, Wolf designs with manufacturability, assembly, maintenance, environmental compliance and the end user in mind. We successfully manage project costs for our customers by reducing parts count and complexity. Wolf designs exploit the use off the shelf components in place of expensive machined components where possible.

We will apply our manufacturing engineering expertise to your new design project or to re-engineer an existing product that needs cost reduction. Many older products are being produced in the same way as they were decades earlier. Wolf can review your existing process routings, materials, vendors, etc. and offer solutions to increase profitability, lower inventory costs, increase throughput and reduce lead-times.

Computer Aided Design (CAD)

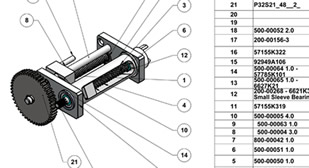

Wolf offers a full complement of 3D computer-aided design and drawing services using SolidWorks, Pro/Engineer and AutoCAD. We will deliver documented technical data packages for complete systems, or simple part drawings for individual components. Documentation is done in accordance with ASME Y14.100 and Y14.5.

Wolf offers a full complement of 3D computer-aided design and drawing services using SolidWorks, Pro/Engineer and AutoCAD. We will deliver documented technical data packages for complete systems, or simple part drawings for individual components. Documentation is done in accordance with ASME Y14.100 and Y14.5.

Many companies still produce products that were documented on a drafting board. Blueprint copies and faded pencil drawing can be easily converted to 3D models so that a lost print does not jeopardize ability to produce a product. Wolf can also supply rendered images of your product or provide a motion simulation of your assembly for presentation or for use on your website.